Are you ready to take your business to the next level? We're here to help you find the optimal solution and make every step of the way easier.

Jetfood Black Premium Inox 7.0 Snack Molding Machine

The JetFood Black Premium Inox 7.0 is now available in industrial versions and is suitable for savoury food manufacturers who wish to increase production and expand their sales.

Their industrial motors offer high efficiency and quality in production, modeling up to 7,000 savory products with crumbled filling, or sweet products per hour. The dough-filling ratio is factory-set at 70 - 30%, ideal for those starting industrial production and requiring standardization of their production.

If you are looking to expand your business and have a greater market reach, this machine is perfect for you!

This forming machine produces savoury and sweet products from 7g to 240g, and the weight can vary depending on the density and texture of the dough.

WHY CHOOSE THE JETFOOD BLACK PREMIUM INOX 7.0

1st: High productivity and efficiency.

If you are looking for high productivity and efficiency, Interlaser has the perfect machine for you!

The Jetfood Premium Inox 7.0 is a state-of-the-art equipment, recognized for its high production capacity and efficiency, which optimizes labor and production time.

With it, you can produce up to 7,000 salted products per hour with weights ranging from 7g to 240g.

2nd: More autonomy in production.

Having autonomy over the production of your savories is important to deliver quality work, right?

Well, the machine's analog panel allows you to have greater control over your production, as well as prevent malfunctions and possible damage.

3rd: Quality and resistance.

Interlaser is concerned with delivering the best to its customers, with great quality and resistance.

The equipment is made of polished stainless steel, has strong gears and shafts [also produced 100% in stainless steel], which provides much more strength and quality to the machine.

In addition, other factors that contribute to its quality and resistance are the steel head, the 2 industrial motors that improve efficiency, the HDPE moulds [required by health surveillance] with resistant pins, the safety sensor to avoid any damage and the acrylic protection, both belonging to the NR12 safety code.

4th: Above average results.

Those who adopt Interlaser machines guarantee autonomy and optimization of processes, which means that you can produce many more savory products in less time.

With this, you increase sales and guarantee significant profits.

5th: European Certification Seal.

The Interlaser European Certification is also present in the Jetfood Premium 7.0 machine and guarantees that our equipment meets the rigorous quality and safety standards required by the European Union.

What does your Jetfood Black Premium Inox 15.0 include?

- 4 different molds: coxinha, ball, pillow and kibbeh.

- 9 dough nozzles for sandwiches and sweets, from 5 grams to 240 grams.

- 1 churro nozzle.

- 5 filling nozzles.

- 1 sausage nozzle.

- Books with more than 100 recipes.

- One year warranty.

- Online technical support 7 days a week.

- Acquisition of accessories and refractions.

- Do you want to expand your snack business on an industrial scale? Jetfood Black Premium 7.0 is the gateway!

Production per hour

7000 - 07 - 10g

Production per hour

3500 - 20g

Production per hour

700 - 100g

Production per hour

350 - 150g

Salty Snacks

Snack Dulces

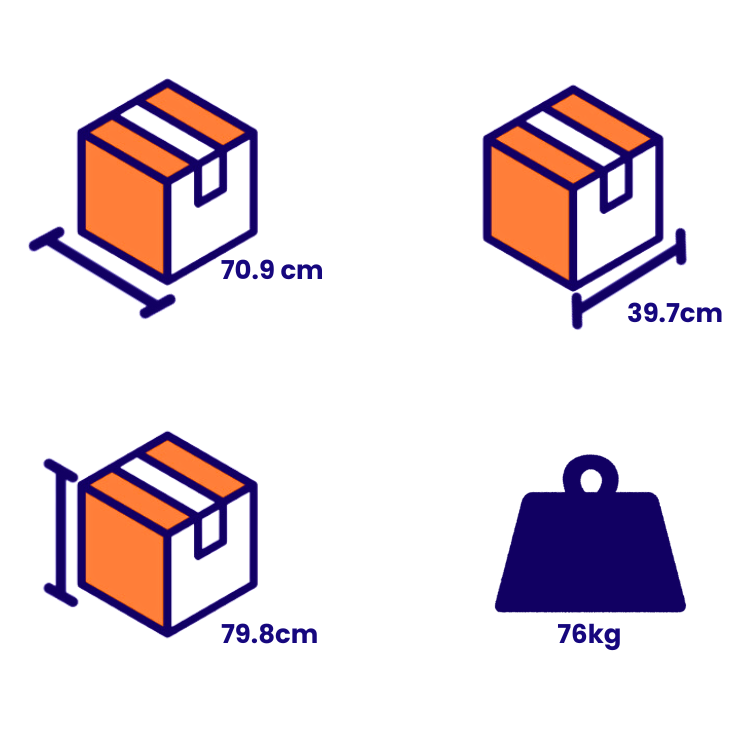

Technical sheet

| Feature | Description |

|---|---|

| Production | 7,000 Snack/hour |

| Electricity | 220 V |

| Security System | NR12 |

| Maximum Consumption | 70kg dough and filling per hour. Factory setting 70 - 30% |

| Snack size | 7g to 240g |

| Panels | Analog/ Isolated Electrical |

| Engines | 3 150 watt motors |

| Gear Bearing | Silent and durable bearing |

| Axles and Gears | Made of 100% steel |

| Structure | Stainless steel |

| Cuba of Dough and Filling | High impact clear acrylic |

| Head | Cast and polished aluminum |